Machines for

efficient production.

The Alpha series: The universal solution

developed by specialists for conformal

coating, dispensing, bonding & potting.

Machines for

efficient production.

The Alpha series: The universal solution

developed by specialists for conformal

coating, dispensing, bonding & potting.

Production competence right down the line.

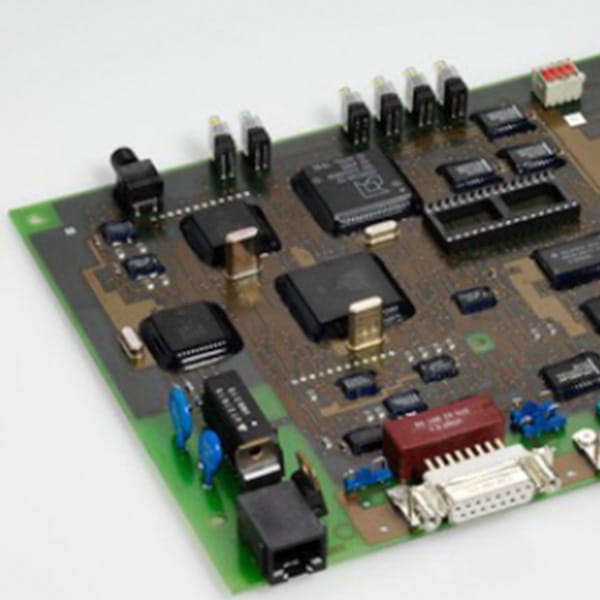

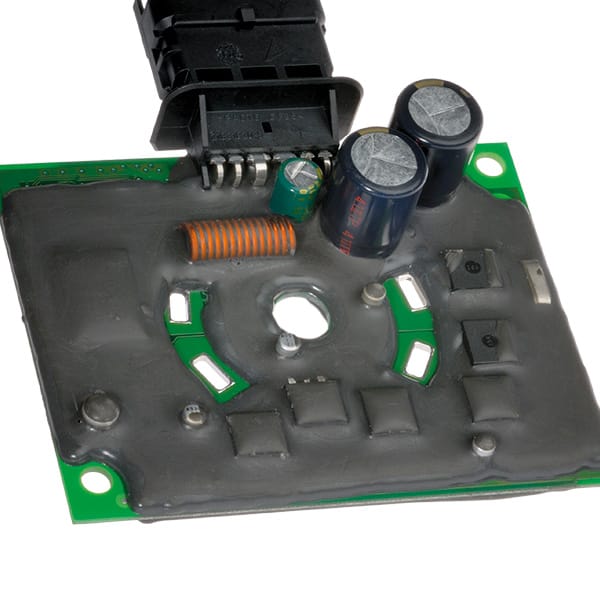

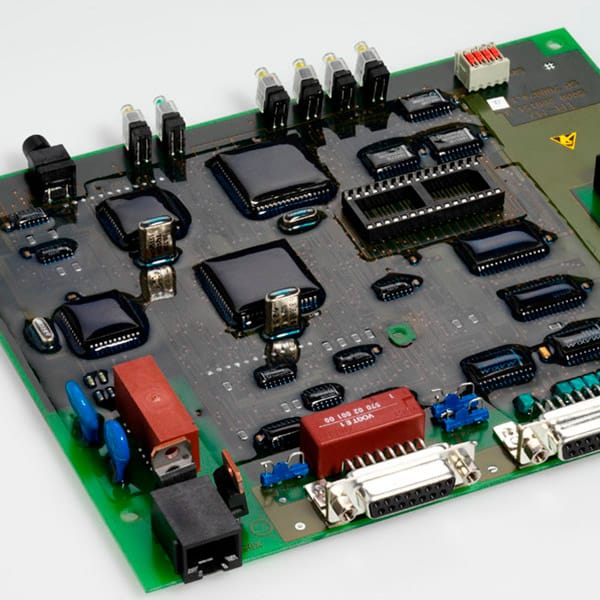

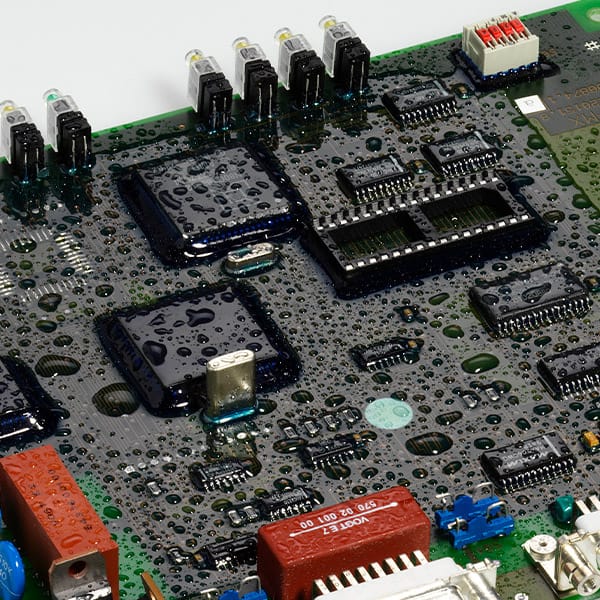

Are you looking for a modern conformal coating platform for sustainable PCB protection? Or are you looking for a processing machine for precision dispensing, for reliable, almost surgically precise bonding or for holistic potting?

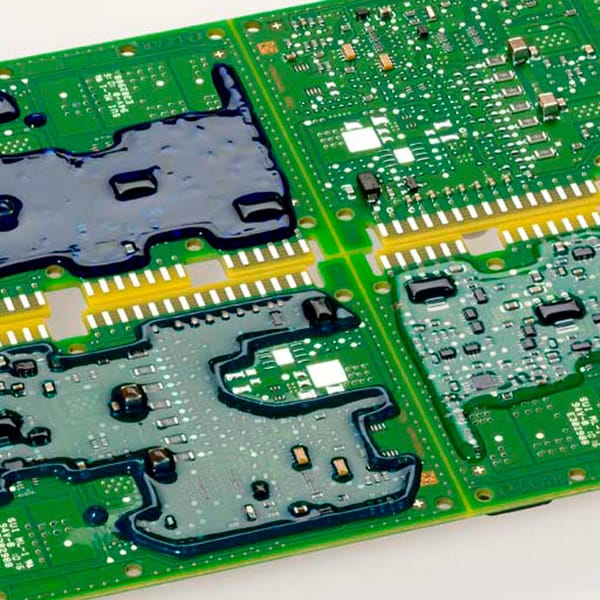

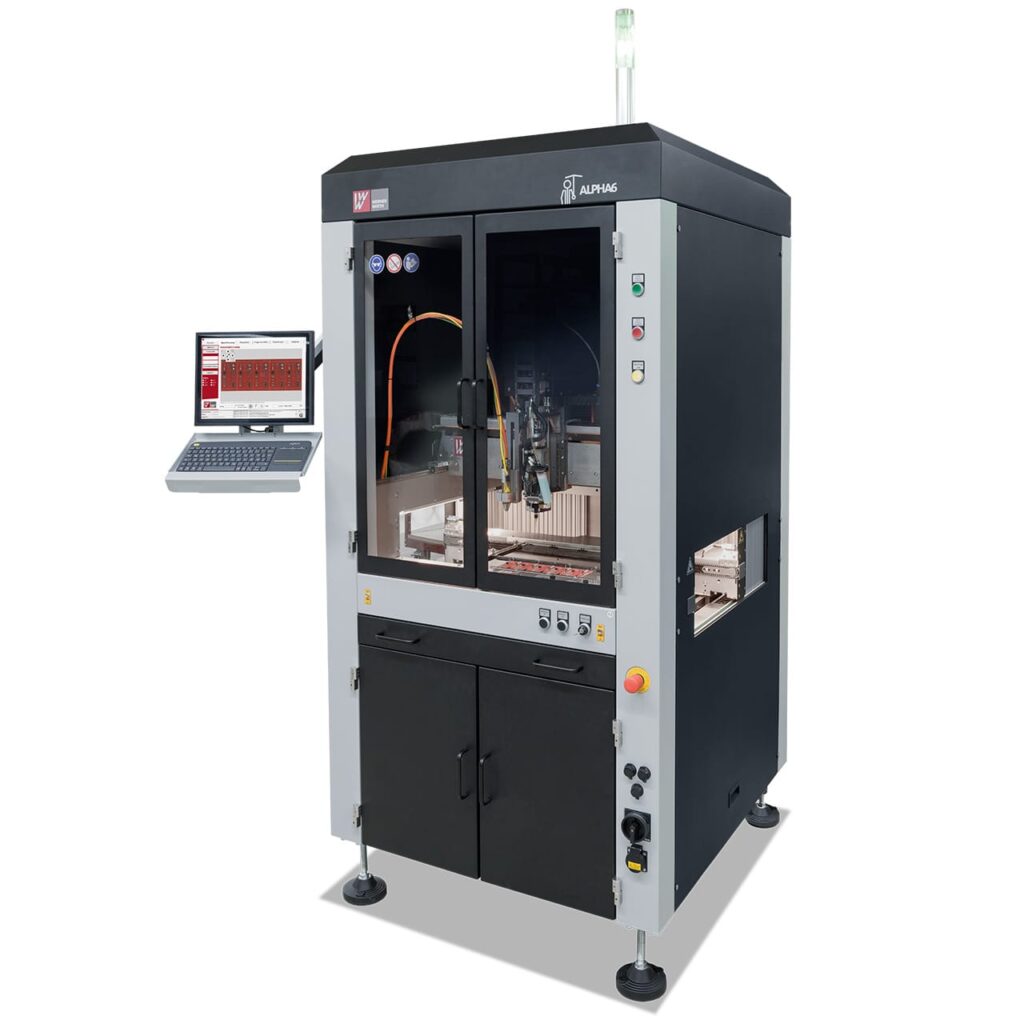

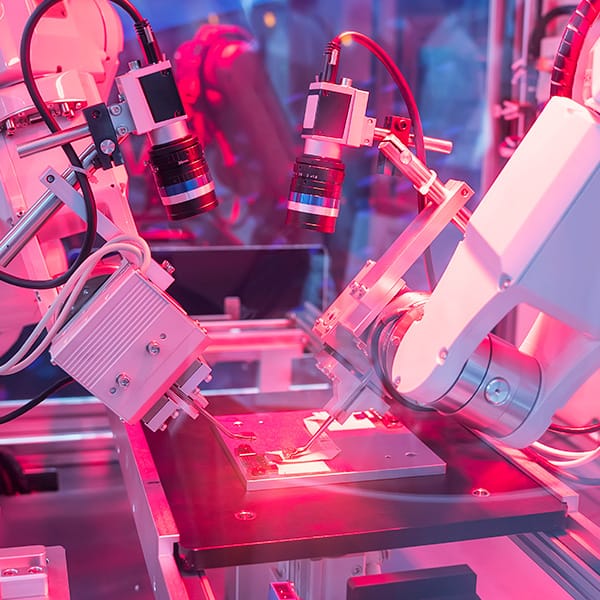

All types of component protection require the right production equipment. WERNER WIRTH will work with you to find and implement the optimum solution. Often this is the Alpha 6, our all-rounder – completely individually designed from the stand-alone solution to the integrated coating line with robust drive system, available with up to 6 axes if required, belt transport system with automatic width adjustment, camera system, black light illumination, MES integration and many other extras.

Discover the Alpha 6 from WERNER WIRTH now: the innovative, compact and extremely user-friendly processing platform for a wide range of coating and dispensing applications. And you can experience first-hand the high precision and coating quality, the repeatability of the application and the flexibility of the system for a wide range of requirements.

WW Alpha 6:

The Alpha 6 coating and dispensing platform is the heart of the highly efficient production line, setting standards in terms of user-friendliness. The compact and flexible processing platform can handle a wide range of coating and dispensing applications with automatic limit monitoring on a 500 x 500 mm coating dispense area at speeds up to 1,000 mm/s and acceleration up to 1 g (10,000 mm/s2) – and all at a high quality.

Designed as a self-contained work cell, this machine can be used for coating and dosing different media as well as for other customer-specific applications, such as surface treatment with atmospheric plasma. It has a positioning accuracy of +/- 0.05 mm on all axes.

The platform features a modern industrial PC with touch screen.

WW Alpha Motion:

Transport of printed circuit boards in the production line between the individual process machines. Varying process lengths allow flexible configuration of the production line.

WW Alpha UV Cure:

Inline UV curing system with modular design, equipped with 4 safety sluices. The UV-Cure curing system picks up the PCBs using a 3-zone transport system and transports the products into the UV tunnel. This is where the media to be cured are exposed to UV light and are stabilised in just a few seconds.

WW Alpha Unloader:

Automatic continuous unloading of the production line into the magazine. The unloader picks up the PCBs from the production line and slides them into the magazine. The magazine is automatically changed in line with the filling levels.

WW Alpha Loader:

Automatic continuous loading of the production line from the magazine. The loader pushes PCBs straight from the magazine onto the subsequent transport module in the direction of the production line.

WW Alpha Motion:

Transport of printed circuit boards in the production line between the individual process machines. Varying process lengths allow flexible configuration of the production line.

The Alpha 6 reliably caters for a wide range of application methods.

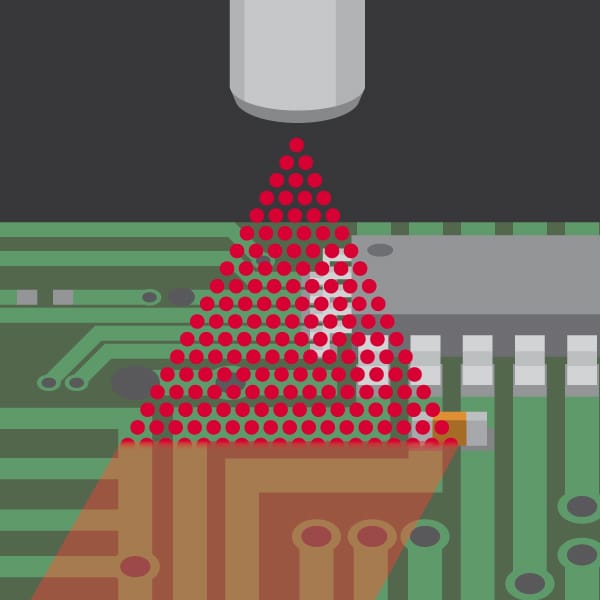

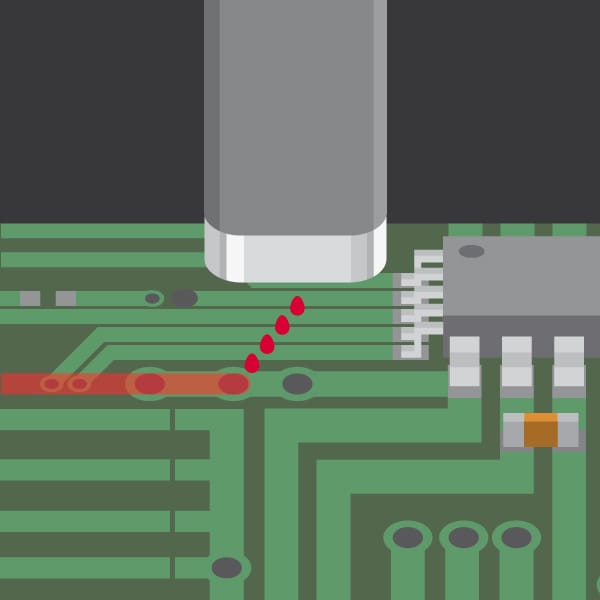

Spraying:

A spray valve can be used for universal and viscosity-independent conformal coating of thin films with uniform film thickness and high coating quality.

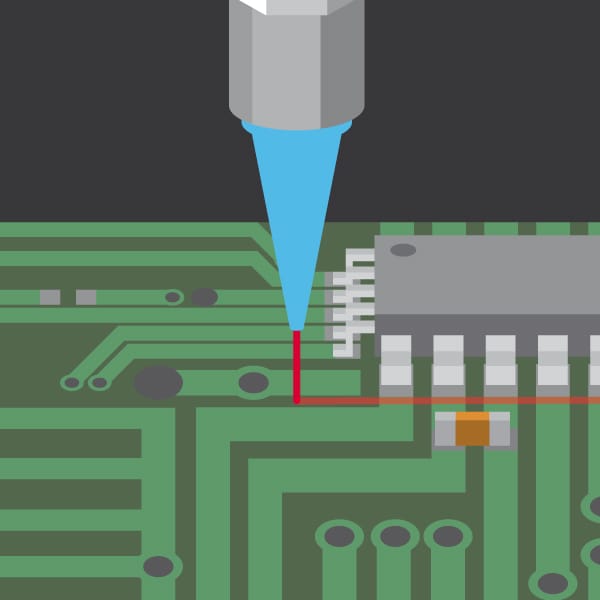

Dispensing:

Dosing valves (time/pressure controlled) are ideal for sealing beads and droplet dosing or microvolume delivery of UV or filler-containing materials.

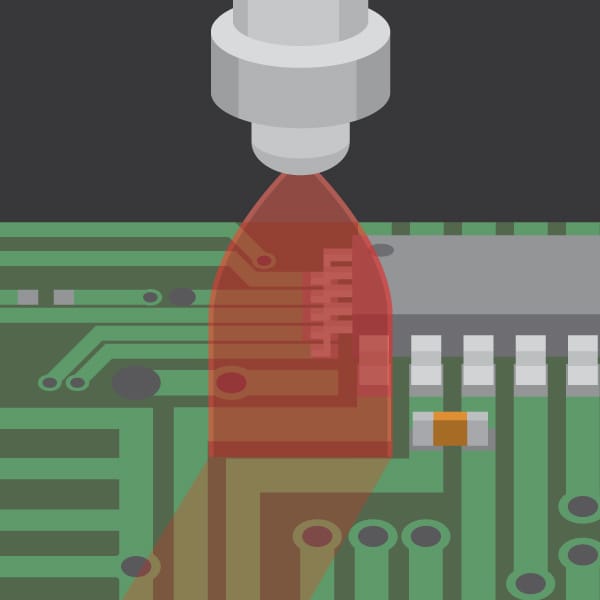

Jetting:

Featuring jet valve technology, the Alpha 6 enables non-contact and high-precision high-speed dispensing with incredibly high repeatability.

Film coats:

Film coat valves are designed for high speed coating – for uniform, wide-area coatings with accurate working edges without splatter. We are happy to advise.

The perfectly fitting production line –

from manual system to large-volume module

Plan your new, customised production line in collaboration with us. Take advantage of our expertise: We are used to thinking about the big picture in a holistic way, taking into account even the smallest detail, and squeezing a few minutes out of somewhere – for even more efficient production.

You can rely on our almost 50 years of experience in the electronics sector and in applications of all sizes. Benefit from our broad range of products and expertise. As an experienced specialist, WERNER WIRTH can handle all types of component protection – from conformal coating, dispensing, bonding and potting to plasma technology. We can provide the appropriate processing machines, materials, valve technology and a complete range of accessories. Our range features extremely high precision, quality and reliability that is rarely matched globally.

We aim to ensure that every element is integrated into the production process with the same precision as a processor on a circuit board.

Industry competence from A to Z

As the only comprehensive specialist in the electronics industry for connection technology and component protection, we provide practical, durably protected contacts on all scales in a variety of industries – from the automotive industry to point-changing systems on railways. The following list is just a small sample of our market expertise, sectors and activities. We would be delighted to discuss the challenges we have already tackled in your industry in a personal meeting.

Automotive

Electromobility

Electrical and electronics

Energy systems

Medical technology

System and machine construction

Made for efficient production –

from stand-alone to complete production lines

PLUG & PLAY

FOR MANY COATING & DOSING APPLICATIONS

SIMPLE AND INTUITIVE OPERATION

HIGH PRECISION, QUALITY & REPEATABILITY

INDIVIDUAL PLANNING &SOUND ADVICE INCLUDED

Test live: hands-on technology.

Arrange your personal appointment now.

Would you like to learn about us, our processing machines and the individual flexibility of the Alpha series in person – and test them live?

Our Technology Days, which are organised specifically for you and your team, offer you the opportunity to experience the complete system live.

Tell us about your specific requirements. Discover the many options in action and see how compact and space-saving the Alpha 6 really is. Test the intuitive user-friendliness – and feel free to bring along your own products for a sample run. When would be the best time for a meeting?

Write to us:

Contact

Werner Wirth GmbH

Hellgrundweg 111

22525 Hamburg

Germany